OUR NEWS

TO AHEAD BLOG

24.4.2024

From passenger to cargo aircraft

Renowned NIAR Institute relies on FiberForm technology from KraussMaffei

Learn more

10.4.2024

Clear the stage for injection molding and automation

The new showroom at Parsdorf

Learn more

9.4.2024

Live @NPE: Future mobility

Clemson University showcases driverless concept vehicle

Learn more

19.3.2024

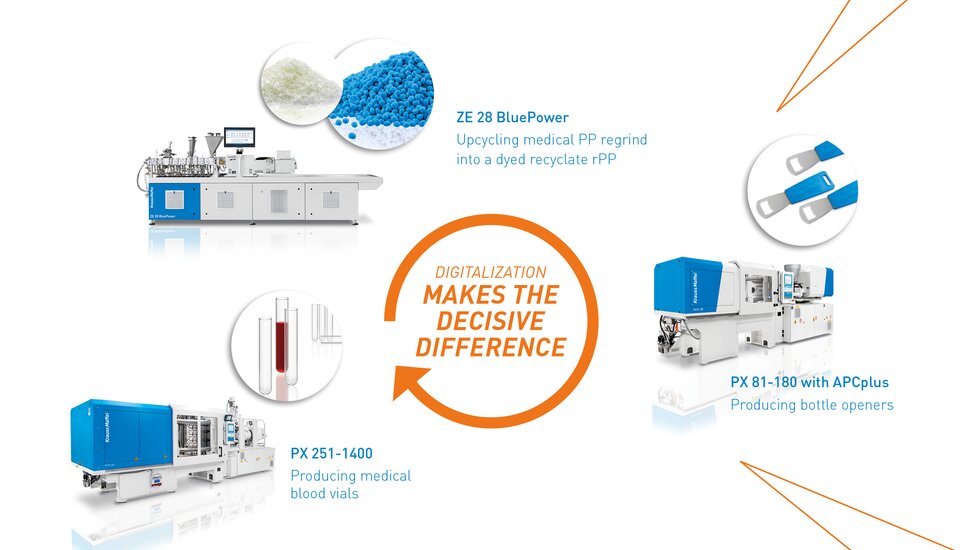

Circular Economy live @NPE

Complete material cycle from medical blood vials to bottle openers

Learn moreCareer at KraussMaffei

to the career portalOUR SOLUTIONS

Automotive

The use of high-quality plastic components in vehicle construction is almost unlimited - so is our comprehensive range for you. Whether it's technically sophisticated components for the car body, a reduction in component weight or intelligent interior surfaces - we offer you everything from development to cost-effective, high-performance series production from a single source.

Circular Economy & Recycling

The quality of the products produced is a key to success in the compounding and recycling of plastic waste. An important prerequisite for this are production processes that run precisely and trouble-free. That's why customers in these industries have been relying on KraussMaffei twin-screw extruders for decades.

Consumer Goods

Attractive design, high functionality, cost-saving efficiency - plastics perfectly demonstrate their advantages in everyday applications. As an experienced complete supplier, we offer you flexible, fully automated machines and systems for your individual production requirements.

Cooling technology & Insulation

Our expertise and technologies in the White Appliance and Insulation sector are your advantage: In our product portfolio, you will find a wide range of cabinet foaming plants, door foaming plants, commercial refrigerators and display cabinets, as well as cabinet and door foaming molds.

Infrastructure & Construction

Whether in building construction or civil engineering, for insulation tasks or for interior design - plastics are convincing in the construction industry due to their long service life, low weight and high flexibility. We accept the challenges of this future market with innovative strength and offer you reliable turnkey solutions.

Medical technology

We are your competent partner for turnkey medical industry injection molding solutions.

Packaging & Logistics

The system solutions we develop are geared toward the highest quality, the shortest cycle times and at the lowest production costs.

Public Transportation & Utility

We offer smart system solutions for demanding thin-walled and IML applications and logistics packaging.